Relative Sizing: Estimating Without the Pain

Remember those "guess how many lollies in the jar" fundraisers? Despite best efforts, everyone's guess was wildly wrong. But if you asked people to compare two jars and say which has more? They'd nail it every time.

As humans we are terrible at estimating the actual size of something, whether it's the number of lollies in the jar or the effort to complete a piece of work. However, we're surprisingly good at relative sizing.

Relative Sizing is one of our favourite ways to create fast, shared understanding of effort without getting lost in hours, days or detailed analysis.

What is Relative Sizing?

Relative Sizing is the act of comparing work items to each other and grouping them by roughly similar effort to help provide reliability of delivery.

Instead of trying to estimate the actual size of something (which we're all terrible at), we simply compare one thing to another (which we're surprisingly good at).

Relative sizing can be used at any level and at any stage of your work.

It’s a two step approach. We start with T-Shirt Sizing - Small (S), Medium (M), Large (L). A familiar, accessible way to get started. Everyone understands t-shirt sizes.

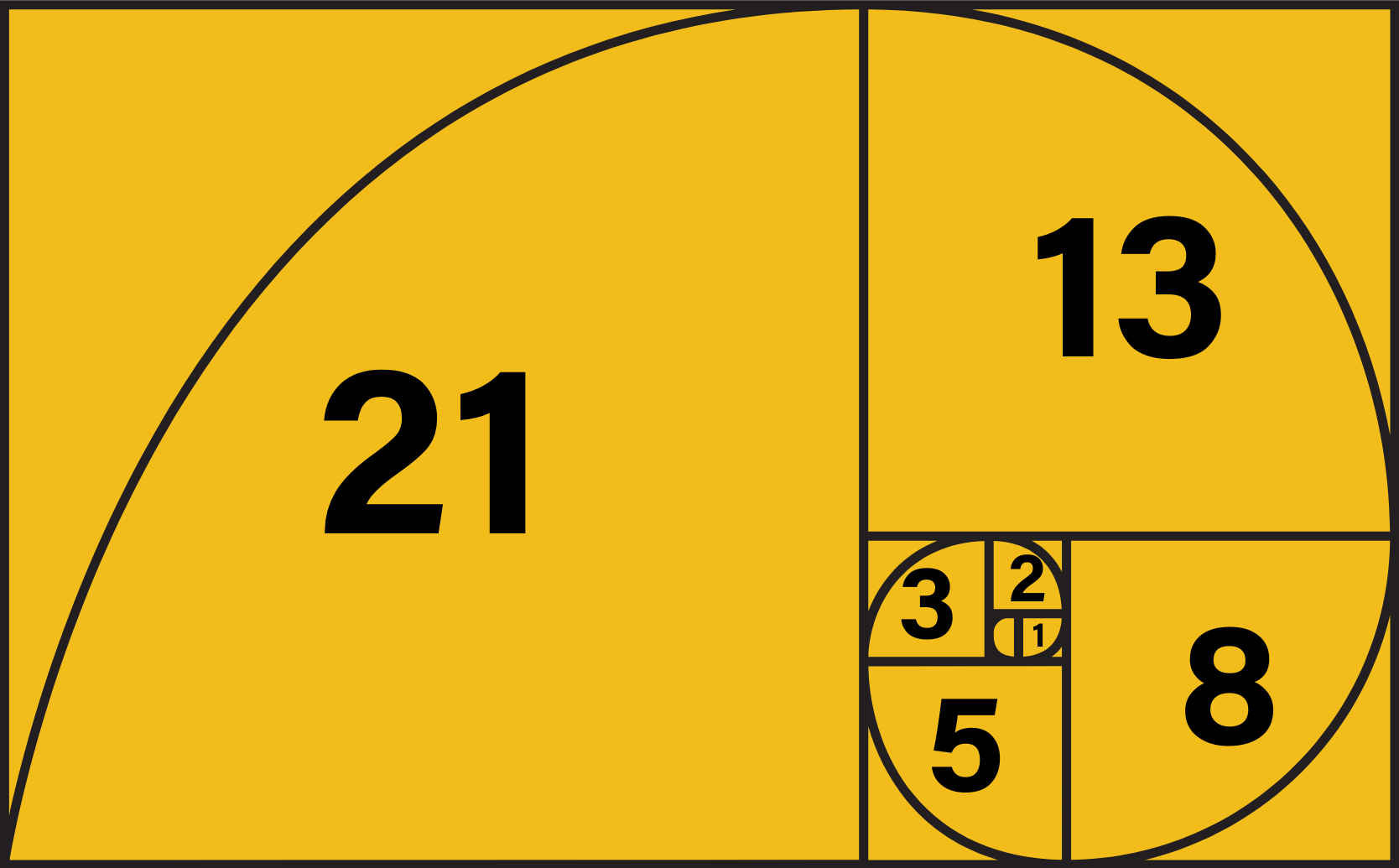

Then we translate to Fibonacci numbers - 1, 2, 3, 5, 8, 13, 21. The Fibonacci sequence starts at 1 and the next number is the sum of the previous two.

Click here to learn more about the Fibonacci sequence.

The reason we need to translate to numbers is that t-shirts don't work well in spreadsheet calculations. The beauty of using Fibonacci numbers for estimating is that as the sequence progresses, the gap between the numbers get proportionally bigger which reflects the growing uncertainty when estimating larger pieces of work.

We translate our t-shirt sizes into Fibonacci numbers to inform our forecasts:

XXS = 1

XS = 2

S = 3

M = 5

L = 8

XL = 13

XXL = 21

Remember that sizing is relative, not absolute. A Medium today should be roughly the same size as a Medium next week. This consistency lets teams forecast based on their own delivery history and leads to increased velocity as team performance grows..

Why We Love It

Relative Sizing helps shift the conversation by:

Creating a shared language for sizing effort across the team.

Surfacing different perspectives and assumptions early, before work starts.

Building forecasting capability based on actual data from delivery history.

Replacing lengthy estimation debates with quick, practical decisions.

Focusing quickly on what matters: is this roughly the same, smaller or bigger?

Recognising that the people doing the work are best placed to size it.

When We Use It

We reach for Relative Sizing when:

Leaders are looking for more reliable delivery forecasts.

Teams are learning to estimate together for the first time.

A team is planning their next sprint or release.

New work is being added to the backlog.

We need to compare the effort of different options.

The beauty of relative sizing is its flexibility. Whether we’re planning three months ahead or refining next week's work, the same approach helps teams build shared understanding and reliable delivery.

How We Do It

We start with T-Shirt Sizing:

We lay out the t-shirt sizing cards as column headers, starting with S, M and L.

We pick an item from the backlog that feels like a Medium size and place it under the Medium column. This becomes our anchor for comparison.

We then take turns sizing the rest of the backlog. For each item we ask:

Is this roughly the same size as the anchor item? If it is, it goes in the Medium t-shirt column.

Is it significantly smaller? If it is, it goes in the Small t-shirt column.

Is it significantly larger? If it is, it goes in the Large t-shirt column.

Once backlog is t-shirt sized, we do a quick scan of the items in each column to confirm everything in that t-shirt column still seems approximately the same size now that we are looking at them all together.

As we scan the S and L t-shirt columns we may realise that we have outliers and we need additional XS and XXS or XL and XXL t-shirt sizes. We let the backlog items tell us what t-shirt sizes we need.

We then move to Fibonacci:

With the backlog items grouped into t-shirt columns, we flip the cards over to reveal the Fibonacci numbers that we use for our sizing forecasts.

Relative sizing is a team-based activity. The collaborative nature of the sizing conversations gives us confidence as it reveals our different assumptions, surfaces hidden risks and builds the shared understanding that turns estimates into reliable forecasts.

Things to Look Out For

The people doing the work should do the sizing - don't let one person dominate or size work for others. You want the wisdom of the crowd, not just one opinion. Different teams might size the same work differently because they have different skills, experience and bias. This is why teams need to size their own work.

Sizing isn't a promise - it's a best guess. It is based on intelligent conversation, spotting unseen opportunities and supporting informed decisions. But don't confuse it with a quote or a contract as it will change as the team learn more.

Perfect consensus is a myth - if people disagree, that's useful information. Talk about why, then make a call and keep moving.

Reliability matters more than accuracy - you're not trying to be right about absolute effort. You're trying to be reliably improve your forecasts over time. If items are sized relatively, then as the team learns more about their delivery capability, it's easy to adapt forecasts and planning well ahead of time.

Don't jump straight to numbers - start with t-shirts. If you skip straight to Fibonacci numbers, teams will often slip back into estimating in actual hours or days. The t-shirt step helps break that “actuals” habit.

Use Fibonacci sequence, not doubling sequence - we prefer the Fibonacci sequence over the simple doubling sequence because our experience has taught us that teams using the doubling sequence, are more likely it to lose their relative sizing way and start translating directly back into actual days or hours.

Capacity increases as teams learn - as your team's delivery skills and product understanding grow, your relative size throughput should increase compared to six or 12 months ago. That's team performance progress. The key is to consistently use your anchor items for all your relative t-shirt sizing guesses. The goal is consistency with the anchors you base your relative sizing on.

Try It With Your Team

At your next backlog refinement, try sizing a handful of items using t-shirts.

Pick something that feels like a Medium item, make it your sizing anchor, then compare the rest of the backlog to it. Don't overthink it, just go with your gut and see where people agree or disagree.

If it's useful, translate those t-shirts into Fibonacci numbers and start tracking how many points your team delivers each sprint. Make sizing a regular part of your backlog refinement, not a one-off exercise. The more you practice, the more reliable your forecasts will become.

Our RAFT Series

✦ Relative Sizing is one of our CoLab RAFTs - Rapid Agile Forecasting & Tracking techniques. Practical tools we use every day in our coaching and training to help teams make work visible and performance-focused.

Version 1, last updated 8 December 2025